Meet the Rural Robots

State of the art robots have increasingly become a feature in bustling urban locations in recent years.

However, the futuristic ‘Gas-Bots’ have not been deployed in rural locations, until this autumn when Britain’s largest gas distribution network Cadent deployed the innovative CISBOT (Cast Iron Sealing Bot) technology to remediate ageing gas mains in Shendish Manor, Apsley, Hertfordshire.

CISBOT was deployed to deal with a troublesome ongoing medium pressure gas escape in the area which was believed to be coming from a number of pipe joints. The location presented major challenges as it was close to a railway line and the pipe ran beneath a golf course and land which is home to both deer and sheep.

Utilising CISBOT meant the work could be carried out without large excavations and meant the gas leak could be fixed, thus avoiding disruption to the local gas services and the railway line, while also avoiding disruption to both the local wildlife and golf course.

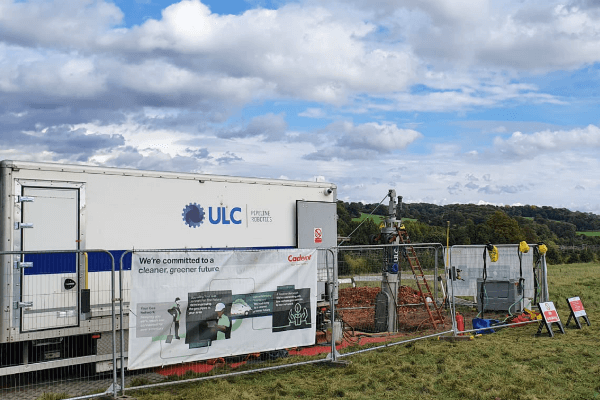

Supplied by contractor ULC Pipeline Robotics, CISBOT requires small excavations to enable it to enter and leave the gas mains through a special insertion tube. Once inside the gas mains it is remotely operated by highly trained human operators working in an above ground vehicle or eco-friendly cabin powered by solar panels. The robot travels along the pipe and injects a special sealant into ageing pipe joints. This process reduces the risk of future gas escapes and can extend the life of a gas main by decades.

CISBOT dramatically reduces the amount of time taken to carry out work to gas mains as well as the number of excavations required and as the robot can also work inside live gas mains with the gas still flowing, local gas supplies do not need to be disrupted.

Cadent Repair Supervisor Eddie Gabbott, who managed the project, explained: ‘This is the first time we’ve used CISBOT in a rural location and just as it’s been a gamechanger in urban locations it’s can also revolutionise the way we do things in rural locations.

‘Ordinarily we’d have had to dig trenches and been here for months, which would have been disruptive for the local wildlife including deer and sheep. With CISBOT however we can work faster, smoother, more economically and with less disruption than with traditional methods.’

ULC Robotics Project Manager Phil Pearson, said: ‘After debuting CISBOT in Hertfordshire in Letchworth earlier this year, we’ve taken things to the next level with this project, which has shown CISBOT can be equally effective in rural as well as urban locations.

‘It helped us fix a leak which could have disrupted both local gas and railway services without causing disruption to golfers and local wildlife.’

Those who may have concerns about robotic technology removing the human element from gas operations can rest easy. CISBOT needs a team of highly skilled human operators above ground to operate it, not to mention all the support staff involved in planning and facilitating the work.

First trialled in London in the early 2010s, the CISBOT technology was developed by New York based company ULC Robotics, who now also have a UK office in Feltham, West London, close to Heathrow Airport.

Though it’s currently not suitable for every type of gas maintenance or repair job, CISBOT is being increasingly deployed by Cadent across its networks. The technology has previously achieved high profile successes in London, including in The Strand and Oxford Street and Cadent has also started rolling out the concept beyond the capital, including East Anglia, where the technology made its regional debut in Norwich.

The use of CISBOT is just one example of Cadent’s innovative approach to delivering its work to keep people connected to safe and reliable gas supplies, with as little disruption as possible.

For more on CISBOT visit: cadentgas.com/about-us/innovation/cisbot.