Plastic Wrap

The issue of our plastic wrap round the magazine has recently been raised on social media – and believe us when we say it’s something we’ve been looking into for quite some time! Like most things, once you start looking into it properly, its not quite as simple as you would think – and we promise that’s not an excuse and we are committed to resolving this for 2020.

Currently, Living magazines (both Berkhamsted and Tring) rely entirely on advertising for their funding – as opposed to say subscriptions – (and currently the advertising rate is only at 25 per cent of Tring magazine’s content as we are so keen to give you a quality magazine with plenty to read rather than a book of adverts). As such, we also include leaflet inserts with the magazine as well as having adverts within the magazine – these provide programmes such as the Tringe Festival and Berkhamsted Arts Trust. Without this, it would be impossible to produce. Furthermore, as the magazine is posted out via Royal Mail to every address in Berkhamsted and Tring and surrounding villages, it needs to be wrapped in something in order to keep it all together.

It definitely does not sit comfortably with us that we currently send it wrapped in polythene, and since this has been raised by readers – who do admit they love the magazine but that this is their main issue with it – we’re very keen to address it and to continue our investigations as to whether there is an alternative.

It definitely does not sit comfortably with us that we currently send it wrapped in polythene, and since this has been raised by readers – who do admit they love the magazine but that this is their main issue with it – we’re very keen to address it and to continue our investigations as to whether there is an alternative.

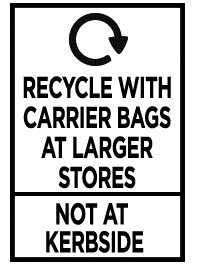

It is important to note out that our wrap can be recycled at supermarkets within the carrier bag recycling bins, but cannot yet be placed into your recycling bins at home.

Oxo-Degradable

We know there is a plastic wrap which is known as ‘oxo-degradable’. According to Defra this is made from petroleum-based polymers to accelerate its degradation when exposed to heat and light. However its still not entirely bio-degradable and how quickly it degrades depends entirely on how it is disposed of. If you’re interested, you can read their report here.

A study by Loughborough University on behalf of Defra showed that incorporating additives into petroleum-based plastics to accelerate their degradation does not improve the environmental effects of the plastic, because the length of time it takes for the plastic to degrade cannot be accurately predicted, and oxo-degradable plastics do not meet established composting standards such as EN13432, so cannot be disposed of in home or industrial composting facilities. They may also have undesirable consequences on disposal facilities and the natural environment.

They concluded that: ‘Oxo-degradation is sometimes promoted as a strategy to reduce litter, but whether this is actually beneficial or harmful, depends on what happens to the plastic fragments in the environment. There is concern that the plastic fragments may be ingested by insects and animals, but this has not been investigated.’ Evidence also suggests that oxo-degradable plastic would not degrade in anaerobic conditions such as those found in landfill.

Polyprint

Polyprint, the manufacturers of the polythene we currently use, say this:

‘The polythene used for mailing is fully recyclable and we fully encourage recipients to return wrappers to us, or to recycle at supermarkets.

‘We believe that the use of polythene is the best and most viable option for packing heavy postal items and many types of food.

‘As long as we are cracking and distilling crude oil into petrol, diesel and other fuels, we are effectively producing the raw materials for the manufacture of polythene.

‘Either we use these products or we have to dispose of them.

‘Polythene usage within the world saves cutting down literally millions if not billions of trees and unlike paper, polythene can be recycled continuously.

‘We do supply oxodegradable film to customers within the mailing industry if they should request it. However, we strongly believe that recycling is a much more environmentally sound option than simply consigning a perfectly good material to landfill.

‘Accordingly, we have put our beliefs into practical action to the point where we suspect we are the only company within the industry to offer to take waste material in from the general public.

‘All of the polythene we supply is recyclable apart from the degradable materials, which are considered as pollutants by the recycling plants, thus the only viable option for their disposal is via landfill or incineration, although we do not have any of the refuse burning power stations that are in use on mainland Europe.

‘We are constantly looking for ways of reducing the carbon footprint of our customers.’

All this aside, we understand entirely that it’s not always practical for people to take these wraps to supermarket plastic bag recycle centres or to post them back to Polyprint, although we can provide the address if you would like to do this.

Which is why we are still keen to find a better alternative.

Alternatives

We have looked into potato starch wrapping but at current printing levels have been told it’s not feasible – due mainly to minimum print quantities and short shelf life rather than the increased cost, which we were prepared to bear.

Alternatives we will also investigate include having a pull-out section of the magazine which contains all the extra inserts thus eradicating the need for the wrapping at all, or increasing the number of adverts within the magazine – although we are loathe to do this as we don’t want to decrease the quality of our product.

You would be amazed at the cost of printing and producing and distributing the magazines, and although there have been suggestions that we could be online only, this makes the magazine an entirely different thing, and we know from market research that MANY of our readers prefer a printed magazine. In fact, there is further evidence of that here: https://www.theguardian.com/media/2018/jul/22/independent-magazines-buck-trend-for-print-decine and here: https://www.printweek.com/print-week/feature/1164839/magazine-sector-finds-ways-to-buck-the-trend

Feedback

We would be very happy to hear any suggestions you may have – and in fact you might have seen the survey in the Summer issue. Last year we also switched our paper to FSC-approved paper, which means it’s been harvested in a responsible way, and we’d like to make a change on the wrapping as soon as we can too. Our commitment to you is to aim to do this for 2020 – we have commitments to our current advertisers for inserts until the end of 2019 anyway.

Owner of Living magazines Alison Page says: ‘I’m as conscious as the next person about plastic pollution and climate change and Living Magazines are not produced by some big, faceless conglomerate, nor have they ever been. We are just local people who are passionate about the areas that we live in and have a desire to help our local communities thrive and to support local businesses to ensure sustainable and viable high streets into the future. We would like to do this positively and we always appreciate feedback from our readers to help us do this.’

We will be bringing you the results of this summer’s survey in our autumn issue, so please do continue to feed back to us – you can complete the survey online here.